Overview

Desert Aire’s GrowAire dehumidification system is helping create community through local sustainable indoor farming of greens and fish in Peach Tree, Georgia. From lettuce to microgreens to herbs to fish, Alō Farms is using alternative farming and innovative methods to create “better than organic” products.

Alō Farms founder, and architect by profession, J.L. “Jefferson” Brown’s involvement in agriculture began 12 years ago after he was involved in filtering water in the Chesapeake Bay and releasing it back into the bay. In addition, he had been involved in mission projects with nutrition needs. One of the trips was to Detroit where he was involved in a project to create gardens where there was a food desert. Jefferson said it hurt to see people starving and was challenged to do something about it.

Introduction

Alō Farms founder, and architect by profession, J.L. “Jefferson” Brown’s involvement in agriculture began 12 years ago after he was involved in filtering water in the Chesapeake Bay and releasing it back into the bay. In addition, he had been involved in mission projects with nutrition needs. One of the trips was to Detroit where he was involved in a project to create gardens where there was a food desert. Jefferson said it hurt to see people starving and was challenged to do something about it.

Jefferson wondered, could he create community around food security and food nutrition? Jefferson, a man of faith, prayed and stepped out in faith, investing his life savings in the vision and goal of creating an alternative farm that would create and serve local communities, Alō Farms. The meaning of “alō” is to feed, to nourish, to sustain, and to develop. He hasn’t realized his vision alone. Others stepped up and he surrounded himself with people with the same passion. He looked at aeroponic, vertical farming, container farming and hydroponic growing techniques before developing the current Alō Farms, an indoor controlled environment agricultural facility. During the process they developed prototypical designs that address the specific needs of the various communities they worked with.

For their latest, their third, Peachtree City, Georgia location, Jefferson took an existing building, and repurposed it into an indoor controlled environment agricultural farm. The plans for the next building include a flat roof and solar panels for with the goal to build the first “net zero farm” in the world.

When planning the Peachtree City facility, Jefferson reached out to Barry Tysor (Anchor Heating and Air Conditioning) who has a strong relationship with Jefferson as a long-time friend and partner. Barry says, “As an architect, Jefferson understood the challenges and has been a great partner with Anchor. He understands what we need. He’s been a good partner.”

When the design development came to HVAC, Tysor recommended Mike Beall of Applied Air Solutions, a long-time Desert Aire representative. Mike, with 30+ years of dehumidification experience, worked closely with the design team to select and provide the best HVAC solution for the application.

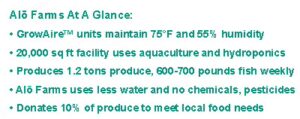

When it’s up to full capacity, Alō Farms’ Peachtree City facility has the potential capacity to double the amount of lettuce grown in Georgia. The 20,000 sq ft Peachtree City facility will produce 1.2 tons of produce and 600-700 pounds of fish per week, employing 16 people to run the facility year round.

According to Jefferson, a comparable traditional farmland equivalent would be 50-125 acres of organic farm, depending on the food product produced. In addition, a traditional farm would require equipment, fuel and storage buildings. In a traditional organic farm, green butter head lettuce requires 22-26 gallons of water per head. Alō Farms uses less than 4 gallons per head and doesn’t use chemicals, pesticides or herbicides. It uses beneficial insects, (lady bugs) to attack the bad (non-beneficial) insects.

In addition, Alō Farms has been practicing techniques to produce lettuce and microgreens differently to make them last longer, up to 4 weeks in a refrigerator (or they’ll buy it back). They can harvest the produce in the morning and then deliver to Atlanta markets by lunch.

Alō Farms is third party certified naturally grown, through CNG. Alō Farms says its produce is better than organic and has the quality and nutrition its customers are looking for. According to Alō Farms, its greens are more nutritious than what is available in big box market stores and that specific greens provide more iron than some dietary supplements.

Alō Farms plans to serve a local food desert by donating 10% of its produce to people in need. In addition, there is a community in the Carolinas that needs food, jobs and opportunities for leadership that Alō Farms plans to provide.

The facility is a controlled environment that utilizes alternative farm and aquaponic techniques. This combines conventional aquaculture (raising fish in tanks) with hydroponics (cultivating plants in water) in a symbiotic environment. This system produces an organic method of fertilizing plants.

In normal aquaculture, excretions from the fish being raised can accumulate in the water, increasing toxicity. In an aquaponic system, water from an aquaculture system is fed to a hydroponic system where the by-products are broken down as nutrients to the plants. Then the water is recirculated back to the aquaculture system.

The Desert Aire dehumidification system (3 packaged GrowAire™ units @ 280,000 BTUH each) at the Peachtree City facility is currently maintaining 75 degrees and 55% humidity. The Desert Aire GrowAire™ units are installed outside on a slab with carefully designed ductwork to deliver the conditioned air to the plant trays. These systems have a unique control algorithm (VPDsync™ Technology) that precisely maintains the space temperature and relative humidity. The systems protect the structure and the plants from forming mold and mildew while in combination with the lights creating the perfect environment to maximize yield of the plants. Although the HVAC system is designed to allow “set and forget” operation, Alō Farms can make adjustments for different plants as needed.

The Alō Farms Peachtree City facility uses Desert Aire’s cloud-based AireGuard™ that is connected to Desert Aire’s equipment. “Being able to get information offsite will be important,” says Barry.

“AireGuard has really helped in troubleshooting and giving the ability to know what’s going on and what’s happening with the airflow, etc.” adds Desert Aire President Keith Coursin. “We get to tune the machine. You change one parameter at a time until you get the profile of the temperature and humidity that you want. AireGuard™ can be a really good tool and we can train Jefferson to be able to look at the parameters he wants you on his screen (computer or phone).”

“Food deserts are also talent deserts and being able to troubleshoot remotely is really important,” adds Barry.

“We’ll look at the data points and see correlations with plant growth and the equipment and data that Desert Aire is providing,” said Jefferson.

“We’re all working together, we’re experts in our field,” explains Jefferson. “All of us have the background and experience that helps each other and what they need to know to be successful. We need to do things that are successful and try to manage it that way. There is a high bar and we put it there ourselves. When you do things with excellence, the rewards come. We all want to be successful.”

Contact Desert Aire today to discuss your controlled environment agriculture grow room (aquaponic, aeroponic or hydroponic) dehumidification needs for growing lettuces, microgreens, tomatoes, peppers or other vegetables.

Find a Desert Aire Sales Rep Near You!

Our network of independent representatives are fully trained on Desert Aire’s dehumidification and DOAS solutions and can assist you in designing and sizing your engineered solutions.