Grow Room Environmental Control | AN26

This application note provides a summary of plant, grow room and indoor farm needs and describes the reasons for the success of Desert Aire's purpose-built, dehumidification-based environmental control systems.

Grow Room Environment Control

Desert Aire developed its GrowAire™ series of temperature and humidity environmental control systems to provide owners with peace of mind their crops will flourish in the most tightly controlled environments – while consuming the least amount of energy. This is a double win for owners.

To access the full application note, please fill out the form —>

Gated Content

Please fill out the form for access.

Introduction

Desert Aire developed its GrowAire™ series of temperature and humidity environmental control systems to provide owners with peace of mind their crops will flourish in the most tightly controlled environments – while consuming the least amount of energy. This is a double win for owners.

This application note provides a summary of plant, grow room and indoor farm needs and describes the reasons for the success of Desert Aire’s purpose-built, dehumidification-based environmental control systems.

Plant Requirements

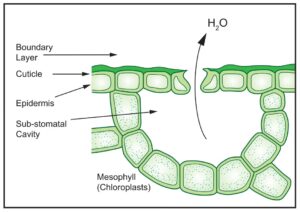

To feed themselves through the process of photosynthesis, plants that are exposed to light convert water and carbon dioxide into food. Photosynthesis consists of two stages, the light-dependent reactions or photo stage; and the Calvin cycle or light-independent stage. Through another process called transpiration, plants use water to carry nutrients throughout their tissues then release this water as water vapor. Plants release water vapor via tiny openings in plant surfaces called stomata to the surrounding, boundary layer air (Refer to Figure 1).

The temperature of leaves and their internal vapor pressures drive this exchange of gases; and the vapor pressures exerted on leaves by boundary layer air. The process of changing internal liquid water into a gaseous state consumes energy. For grow rooms and indoor farms the sources of this energy are facility lighting systems.

Gases and liquids move from areas of high concentration to low concentration. Vapor pressure differentials, sometimes known in the grow room industry as vapor pressure deficits, drive transpiration and provide the forces for nutrients to be brought from roots to the upper areas of plants. Because the vapor pressures inside of hydrated plants and their stomata is high, water vapor will exit the stomata if the air outside of leaves has lower vapor pressures. Think of the plant leaf and its stomata as a series of little balloons that are filling with moisture-laden air. We all know that when you heat air it expands. When the pressure inside the balloon is greater than outside the air escapes the balloon. The light energy as well as the chemical reaction created by the photosynthesis process provides the heat that expands the air inside the stomata and creates a higher vapor pressure in the stomata. At the same time the dehumidification system is also providing air outside the stomata that has a lower vapor pressure.

In grow rooms and indoor farms it is important to surround plant leaves with air that has lower concentrations of water vapor than their internal vapor pressures; establishing and maintaining the conditions for optimal transpiration rates. This builds on the work of HVAC system designers and grow room owners. They collaborate on the design of ductwork and air distribution systems that ensure air (a combination of supply air from air handlers and additional localized fans) is dispersed evenly throughout plant canopies at desirable airflow rates. This ensures that localized areas do not form that would have higher vapor pressures should the canopies retain the transpired moisture.

In general the greater the transpiration rates the more nutrients will travel through plant root systems, creating faster growing cycles. There are upward limits to these transpiration rates however.

Transpiration rates that are too high can cause unhealthy conditions that lead to wilting and tip-burn. The key to healthy transpiration rates is to provide controlled vapor pressure differentials as well as stable temperature conditions. Air directed at plant leaves should be at temperatures above design dewpoints so that condensation on leaves does not occur and create conditions for mold and fungi growth.

Therefore in order to have optimized plant growth indoor growing facilities must control space temperatures as well as absolute humidity levels. More importantly, these must be controlled uniformly across and throughout plant canopies.

Standard System Problems

When the commercial cannabis marketplace was in its infancy most growers adapted their knowledge from small scale and residential grow operations. To maintain indoor conditions in those operations they used standard air conditioners and small portable dehumidifiers. When they apply this approach to today’s considerably larger commercial operations they create problems for themselves. Growers soon become frustrated with the following issues:

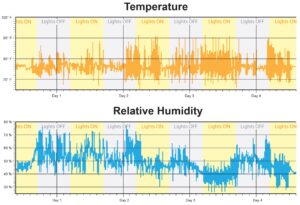

- Temperature and relative humidity are constantly fluctuating (See Figure 2).

- The air conditioners and dehumidifiers are not controlled together.

- Relative humidity is the incorrect control parameter.

- The air conditioners must be oversized to remove excess heat introduced into the spaces by the small portable dehumidifiers. This brute force method creates fluctuating temperature and humidity conditions. Significantly, this method also wastes large amounts of energy as the dehumidifiers put heat into the spaces and then the air conditioners must switch on to take the heat out of the spaces.

Introducing Dewpoint

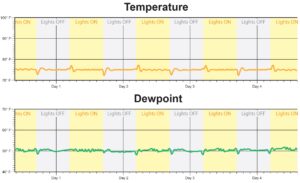

Relative humidity is a misapplied term. It is often used in place of absolute humidity. The key is the word “relative.” As the air temperature increases, the total volume of the air molecules increases. Conversely when air temperature decreases, the volume of the air molecules decreases. Water, however, is not compressible. Therefore given a specific amount, it will always occupy the same amount of volume. Figure 3 illustrates graphically how this works. As moisture-laden air is heated or cooled the air volume changes but the amount of moisture in the air does not.

This is important to understand because water condensation occurs at an absolute humidity concentration regardless of its relative humidity. This is known as the constant dewpoint temperature, the key metric in creating vapor pressure deficits for healthy plant growth.

GrowAire™ Solutions And Success

The phenomenon of relative humidity presents some challenges for conventional dehumidifier control. Since somewhat small changes in the temperature can impact the relative humidity, monitoring the relative humidity of a space for dehumidification control can cause premature indexing to the dehumidification mode, hunting or short cycling. Although humidity control is set and read in terms of relative humidity, Desert Aire’s GrowAire™ systems constantly convert the setpoint and sensor values internally to dewpoints. Since dewpoints are direct measurements of the total moisture contents in air, dewpoints provide more stable values and are more representative of the required changes in operating modes or stages of GrowAire™ systems.

Dewpoints also reflect the true operational conditions growers desire. More knowledgeable growers will understand that vapor pressures in the air are the main driving factors in the growth of plants. Like dewpoints, vapor pressures are not dependent on relative humidity.

Internally, GrowAire™ systems calculate the desired dewpoints based on temperature and humidity setpoints and then control indoor environments based on these dewpoint values. Operation based on dewpoints is one of the main advantages of GrowAire™ systems, providing stability and efficiency. This is especially important when conditions change from photosynthesis periods to dark periods and vice versa; and there may be separate temperature and humidity setpoints programmed. Figure 4 demonstrates the stability of using this control method.

GrowAire™ systems use a unique controller that has a zone reset function for both temperature and dewpoint control. In everyday terms, this means that systems are constantly monitoring the difference between the setpoints and the actual grow room conditions. As differences increase, the calculated supply setpoints of temperatures or dewpoints decrease. The GrowAire™ systems constantly monitor intake conditions to determine the number of compressor stages required to bring conditions entering the intakes to the calculated supply conditions; and to engage the correct number of compressor stages to do so.

While this is occurring, the operating controllers also modulate the hot gas to the reheat coils. This maintains the temperatures leaving the systems to the current commanded supply air temperature setpoints. Because GrowAire™ controllers are looking at both temperatures and absolute humidity values, they can eliminate the wild swings of conventional systems.

Conclusions

Desert Aire’s GrowAire™ solutions combine the functions of air conditioners and dehumidifiers, helping to establish and maintain the conditions for optimal transpiration rates and plant growth. Desert Aire bases GrowAire™ solutions on unique refrigeration-based dehumidification systems that meet the high cooling and dehumidification demands of lights-on modes, without the need to oversize the environmental equipment for the added heat rejection associated with conventional portable dehumidifiers. In lights-off modes, they continue to maintain dewpoint control to protect the plants and crops without over-cooling the grow rooms and indoor farms.

Share or Download

Ask A Question

Related Products

GrowAire™ Series

Desert Aire’s GrowAire™ Dehumidification Systems are specifically designed for indoor farming and ...

View Details

GreenAire™ Series

Desert Aire’s GreenAire™ Dehumidification System offers you complete indoor climate control and su...

View Details

DriCure™ Series Dehumidifier

Desert Aire’s DriCure™ Dehumidification Systems are specifically designed as an all-in-one solutio...

View Details

TotalAire™ Series

TotalAire™ Series DOAS systems offer our widest range of performance options including energy recove...

View Details

Find a Desert Aire Sales Rep Near You!

Our network of independent representatives are fully trained on Desert Aire’s dehumidification and DOAS solutions and can assist you in designing and sizing your engineered solutions.