Basic Dehumidification Refrigeration Flow Diagrams | TB02

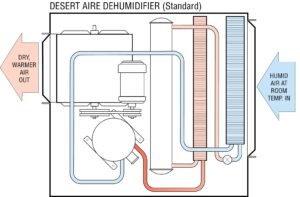

This technical bulletin will show how a refrigerant type dehumidifier recovers the heat from the water vapor and disperses the energy to different heat sinks.

Gated Content Overview Headline

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Gated Content

Please fill out the form for access.

Overview

This technical bulletin will show how a refrigerant type dehumidifier recovers the heat from the water vapor and disperses the energy to different heat sinks.

Heat Sinks

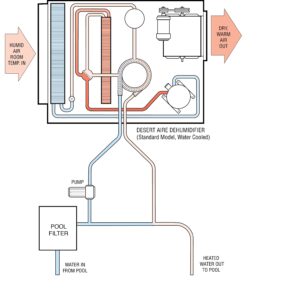

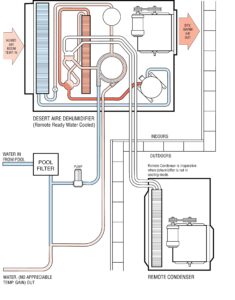

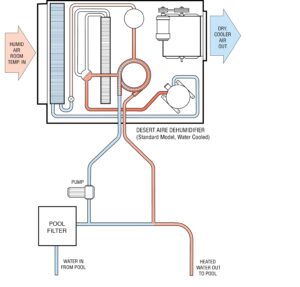

Refrigerant type dehumidifiers are a closed loop system which effectively transfers both latent and sensible heat from an indoor environment to variety of alternate heat sinks. The key point to understand is that the refrigerant which gained the energy must dissipate the energy or the system will shut down because the internal pressure would be too high. The most common heat sinks are listed here, along with a short description about how they remove energy.

REHEAT – A reheat or condenser coil is present in all DESERT AIRE dehumidifiers and is the most common heat transfer method. The actual heat sink is the air from the evaporator coil which has been cooled down when it released its energy to the refrigerant. This cool air now passes over the hot condenser coil and is reheated. Thus the air temperature leaving the dehumidifier is higher than the air entering. The exact temperature differential is a function of how much latent energy (moisture) was present in the

room and the run time of the compressor which also generates heat as a by-product. This method is also known as air to air exchange.

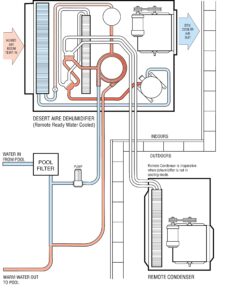

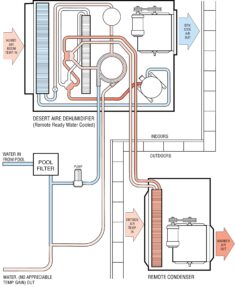

WATER HEATER COIL – In this method, an additional component is added between the compressor and the reheat coil. This component is generally a tube in tube heat exchanger which allows water to absorb the heat from the hot refrigerant. A diverting valve controls whether the refrigerant goes to the air reheat coil or the water heater coil. The application will dictate which heat sink has priority. There are several different water sources of heat sink. Examples are listed below:

- Pool water

- Spa water

- Potable water

- Cooling tower water

- Hydronic heat water

- Industrial process water

The actual water heater coil is selected to be compatible with the water used. For example: copper, cupronickel, or stainless steel.

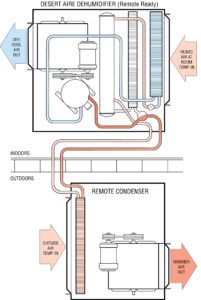

REMOTE CONDENSER – In this situation, all other heat sinks for recovery of heat have been exhausted. In order for the dehumidifier to continue working, an additional heat sink must be added. This becomes similar to a standard air conditioner by adding a condenser outside of the conditioned space. When all other heat sinks are at a proper condition, then a valve diverts the hot refrigerant outside where the remote condenser dissipates the heat to the surrounding environment. This condenser must be sized to the dehumidifier to insure proper charging and operation.

When the remote condenser is utilized, the cool air from the evaporator coil does not get reheated. The air leaving the dehumidifier is cooler than the entering air. The total air conditioning capability is a function of the latent and sensible load in the room.

SYSTEM DESIGN – In designing a dehumidifier, there are several key specifications which must be considered.

First, how much moisture must be removed from the room? This is generally calculated in pounds per hour of water. Every application can have several sources of moisture such as open water vessels, infiltration or processes. All of these sources must be considered as well as what design condition is acceptable. With this information a dehumidifier size can be selected. Refer to other DESERT AIRE application notes for assistance in the sizing procedure.

Once a size is selected, then a decision on what heat sinks are available must be made. Will the room handle the extra heat load? Is a water supply available? Answers to the heat sink question will then dictate whether an air cooled or water cooled unit is selected and if a remote condenser is required.

Proper installation of the dehumidifier into the total HVAC/R system takes careful planning. All of the heat available from the dehumidification process is derived from the compressor and the conversion of latent energy through refrigeration technology. The design engineer must make the decision whether the latent load will always be present. With a seasonally fluctuating load or maintenance condition, such as drainage of an indoor pool, supplemental heaters must be added to compensate for the lack of heat from dehumidification. If room temperature is critical the supplemental heat source must be sized to handle the total heating requirements.

Another factor requiring attention is condensate from the dehumidifier. Some local codes state that condensate be plumbed to a drain. The dehumidifier employs a gravity drainage system. An unpressurized drain connection or a condensate pump must then be added.

Related Products

Aura™ Series DOAS Units

Aura™ Series DOAS systems give you the flexibility to design energy saving solutions for meeting IAQ...

View Details

DriCure™ Series Dehumidifier

Desert Aire’s DriCure™ Dehumidification Systems are specifically designed as an all-in-one solutio...

View Details

ExpertAire Horizontal (LC), Vertical (LV) & Packaged (LCQ) Series Dehumidifier

Designed for high efficiency and long life, Desert Aire’s ExpertAire™ commercial dehumidification ...

View Details

ExpertAire Wide Temperature Range (LW) Series Dehumidifier

LW Series dehumidification systems keep space humidity low while controlling outdoor air to ensure low...

View Details

GreenAire™ Series

Desert Aire’s GreenAire™ Dehumidification System offers you complete indoor climate control and su...

View Details

GrowAire™ Series

Desert Aire’s GrowAire™ Dehumidification Systems are specifically designed for indoor farming and ...

View Details

SelectAire Plus™ (SP) Series Dehumidifier

Designed specifically for large 50 meter pool applications, the SelectAire Plus™ Series modular dehu...

View Details

SelectAire™ Series Dehumidifier

The SelectAire™ commercial dehumidification systems are ideal for large-scale moisture removal appli...

View Details

SwimAire™ Series Dehumidifier

With 39 to 112 lbs/hr of moisture removal capacity, 3,000 to 8,500cfm of air handling and 8 to 23 tons...

View Details

TotalAire™ Series

TotalAire™ Series DOAS systems offer our widest range of performance options including energy recove...

View Details

VerticalAire™ Series

Desert Aire’s VerticalAire™ Series DOAS systems provide you with scalable IAQ solutions for indoor...

View Details

Find a Desert Aire Sales Rep Near You!

Our network of independent representatives are fully trained on Desert Aire’s dehumidification and DOAS solutions and can assist you in designing and sizing your engineered solutions.