HVAC Requirements of Water-Cooled Lights

This blog will provide context for the cultivator to understand the overall indoor grow room design requirements of a facility that will use water-cooled lights instead of the traditional air-cooled lights.

Gated Content Overview Headline Default

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Gated Content

Please fill out the form for access.

Introduction

It’s interesting the claims being made by water-cooled grow light manufacturers. This blog will provide context for the cultivator to understand the overall indoor grow room design requirements of a facility that will use water-cooled lights instead of the traditional air-cooled lights.

I’ll look at the magician-like claims made about the HVAC system requirements for indoor grow rooms and get the sleight of hand removed from the discussion.

From my research there are some very good features of water-cooled lights, such as increasing light life time and reducing the decay of the light spectrum over time. However, claims that the lights reduce the amount of HVAC equipment or their operating costs are not totally truthful if the indoor grow facility building as a whole is evaluated.

All lights give off heat whether they are high intensity discharge lighting, LED lighting or fluorescent lighting. Some of this heat is required within the grow room, but not the full heating load that these lights produce.

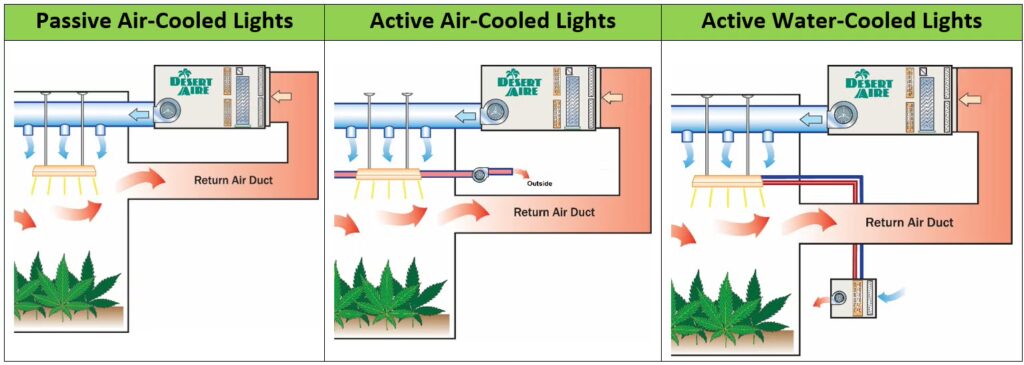

3 Ways Lights Can be Cooled

- Passively cooled by the HVAC equipment servicing the room for cooling and dehumidification.

- Encasing the lights to create a sealed system and then using air to pull the heat to the outdoors with the HVAC equipment servicing the room for the remainder of the cooling and all of the dehumidification.

- Imbedding water cooling elements as part of the light and then connecting the lights to a water loop for an external HVAC system rejecting this heat energy with the HVAC equipment servicing the room for the remainder of the cooling and all of the dehumidification.

A unit of heat energy that must be removed from a room must have a corresponding system to remove that energy. I’ll use an analogy to explain.

One Truck or Two?

Let’s compare the loads that a truck must remove from a project. If we have a total of one ton of rock to remove, we could make a decision to remove it in the following two methods.

- A single one-ton truck removing the full one-ton load

- Two ½ ton trucks each removing half the one-ton load

Which method would cost you the least in capital expenditures and which one would cost you the least in operating costs?

The answer is the single truck method. One truck would cost less than the two smaller ones. And one truck would cost less to operate with less fuel, one driver, one insurance payment and only one service maintenance.

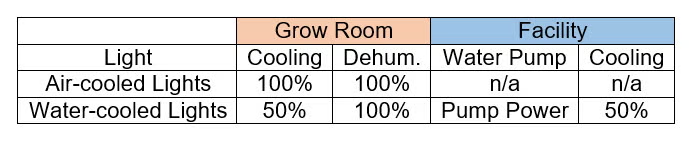

Let’s analyze the requirements of air-cooled lights vs. water cooled lights from an HVAC perspective using a simplified table showing where the cooling and dehumidification load is being removed as a percent of total.

For the water-cooled lights the sensible removal is being transferred from within the grow room to a system (typically a chiller) located outside the room, but part of the facility. Remember every unit of heat must be removed by something.

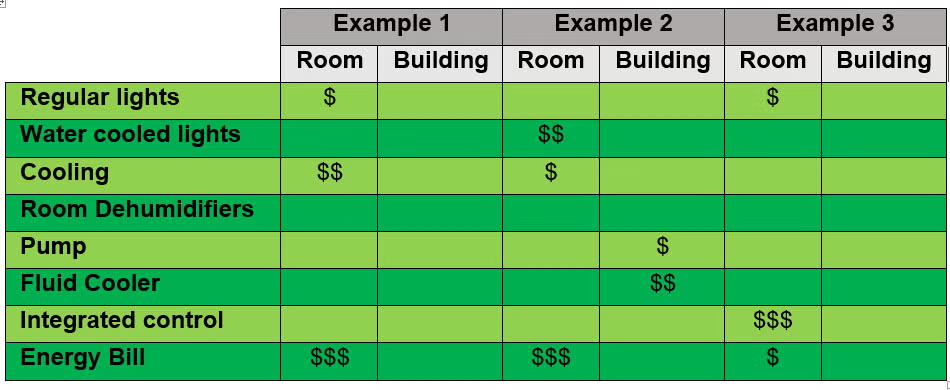

Let’s look at three examples of grow rooms with various solutions for lights, AC equipment, dehumidification equipment and the resulting energy bill.

Example 1: Regular lights, comfort cooling AC, room dehumidifiers, and a large energy bill

Example 2: Water cooled lights, smaller comfort cooling AC, Room dehumidifiers, a pump, a fluid cooler and a large energy bill

Example 3: Regular lights, integrated control equipment, smaller energy bill.

The interesting technical load analysis that is often over looked is that with the new LED lights, the sizing of the integrated systems for the grow room is sized for the dehumidification load and that system will have all of the capacity to handle the cooling load. So with integrated systems there would be no downsizing of equipment when switching to water-cooled lights, but rather an increase in overall equipment spend.

It could be justified if conventional air conditioners were paired with separate dehumidifiers that the size of the equipment could be reduced, but a broad claim is just a slight of hand by the magician and total system analysis must be completed to see if the good benefits of water-cooled lights would justify an increase in HVAC costs.

Ask A Question

Find a Desert Aire Sales Rep Near You!

Our network of independent representatives are fully trained on Desert Aire’s dehumidification and DOAS solutions and can assist you in designing and sizing your engineered solutions.